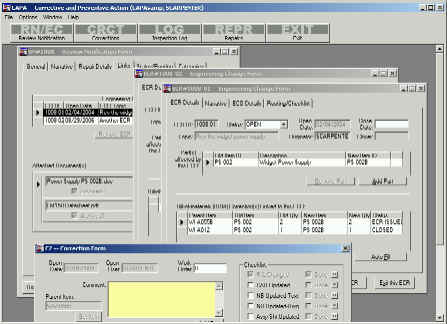

The AcQualis™ CAPA Application

CAPA parent screen showing an RN, 2 ECR’s

and 2 Corrections

CAPA-centered quality software for medical devices

The AcQualis™ application handles CAPA (Corrective And Preventive Action) events

in manufacturing, for compliance with ISO 9001/2000, FDA and CE medical device

requirements, including 21 CFR Part 11 requirements for electronic documents.

Key Benefits

| Manages CAPA (Corrective and Preventive Action) forms |

| Manages engineering changes |

| Manages document and bill-of-materials corrections |

| Manages inspection logs |

| Interacts with ERP inventory and bill-of-materials |

The AcQualis™ system is focused on...

| Addressing the special significance of CAPA for

FDA-regulated device makers, leading quality-management teams to spend more focused

time on CAPA, generating clearer, fuller and more complete

documentation. |

| Enhancing team collaboration - This system is the

only one we know that captures people's interactions so that in the

process of resolving an issue as a team they create a fully compliant

CAPA document, saving time and money. |

Presentation

Click here for a presentation that focuses on the unique advantages of

Commonwealth Software’s AcQualis™CAPA application:

Product Description

AcQualis™ is a collaborative application that gathers

critical quality-related

information from throughout the organization, contributed by people in a variety of roles. It interacts with the company’s

ERP system (Enterprise Resource Planning).

More specifically, the program manages a database made of several

different types of documents connected with Corrective and Preventive

Actions: (1) Review Notification (RN) forms - forms that trigger a

committee review, (2) Repair forms - handled as a subtype of RN, (3)

Engineering Change requests / Engineering Change orders, (4) Corrections

to Bills-of-materials and other documentation, and (5) Inspection Log

entries. The central CAPA document (RN) is more than just a

non-conformance form - it is not just negative - our application also

functions as a multi-ported, instantly accessible suggestion box, which

everyone in the organization is empowered to use, whenever there’s an

opportunity to identify a potential improvement in a product or

process.

Interlocking forms - Review Notification forms, Engineering

Changes and Correction forms have an interlocking relationship: A Review

Notification cannot be closed until its dependent Engineering Change(s)

are closed, along with other required actions. An Engineering Change can’t

be closed until its dependent Correction(s) are closed.

Correction forms are also used alone to

implement a simple but powerful workflow solution for correcting drawings,

bills-of-materials and other critical documents.

Focus on collaboration

- The application's distinctive features all contribute to enhance

collaboration; together these features present an exceptionally rich

document model:

|

Threaded narratives - The threaded narrative

fields work like a “blog” or threaded discussion, and identify the

contributions of each participant with name and date, showing vividly how

the issue was tackled and resolved. Users compose comments in a separate

window where spell-checking is available. |

|

Rule-based document life cycle management - A

document passes from one phase to the next in its life cycle when the

STATUS is changed, Configurable document life cycle means that status

identifiers are defined using a Status List Management screen. Each

change of status is validated using a set of Status change validation

rules. Rules are developed using a Rules Management screen. |

|

Configurable checklists - Checklists are managed

both at the document level by clicking the Required box and

system-wide using the Checklist Management screen. Name and

date are recorded for each checkmark made. |

|

Document-style concurrency –

several users can view a document while only one may edit it –

read/only users are notified when the document becomes available for

editing. |

|

Attached Documents - Documents from any

Windows application (Word processing, spreadsheet, image, CAD) can be

attached in two stages: an active stage where they are editable

in place from any workstations that has the host application, and an archived

stage where they can be read but not changed. |

|

Indelibility - Central to the design of this application is the

need to make it behave like indelible “ink on paper,” to disable

the computer’s normally-desirable ability to allow a user to change a

document without leaving a trace of the document’s state prior to the

change. CAPA uses many innovative methods to apply this constraint and to

communicate the state of the data to its users. |

Architecture - AcQualis™

is

developed using the Windows Multiple-Document Interface (MDI) and

ADO database connectivity. The CAPA data is kept in the form of a secure

relational database (MS SQL Server 2005). The ERP data comes via ODBC

or OLEDB from the ERP system’s

native database platform. Everything that persists in the application is

stored in the relational database, which handles the mechanics of sharing

data among multiple users and allows unlimited reporting and analysis

using the CAPA application’s own reports or such external tools as Crystal

Reports, Quantrix, Cognos, Microsoft Access, Excel.

|

|

|